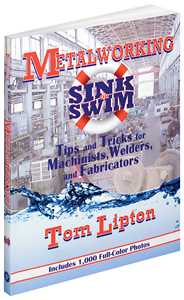

Metalworking Sink or Swim

- Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators

- By Tom Lipton

- 305 pages, paperback, 8½" x 11"

- ISBN 9780831133627

- Publication date 2009

Includes nearly 1,000 full-color photos, as well as numerous illustrative stories that help users easily understand the material presented and the techniques provided.

Chris' Tips

Chris' TipsChapter 1 Diving In Welcome to Sink or Swim; Personal Learning Attitude; Shop Environment; Thursday Nights; What's A Journeyman Anyway?; Format

Chapter 2 Brain Food Communication; Drawing and Sketching; Minimizing Screw Ups; Accuracy; Speed; Shop Math; Mass, Volume, and Area; Angles and Shop Trigonometry; The Metric System; Computers and the Metalworker; Dumb and Dumber; Want to Make a Million Dollars? Some Things That Really Need to be Invented

Chapter 3 Bean Counter Lounge

Chapter 4 Get the Shop Set Up Floors; Light; Food Preparation Area; Food Consumption Area; Heating and Cooling; Workbenches and Tables; Air Supply in the Metalworking Shop; Raw Material Storage and Handling; Material Identification and Characteristics; Safety Equipment; Tool Crib; Bench Work; Filing; Saws and Sawing; Rigging and Lifting

Chapter 5 Manual Lathe Threading in the Manual Lathe; Multiple Start Threads

Chapter 6 Manual Milling Machine Bridgeport Mills; Suggested Improvements; Spherical Surface Generation in the Manual Milling Machine

Chapter 7 CNC Mill Working with CNC Equipment; CNC Mill

Chapter 8 CNC Lathe CNC Lathe Programming

Chapter 9 The Welding Shop Getting Started; Layout Work; Some of My Favorite Hand Tools; Welding Table; Brake Bumping

Chapter 10 The Lost Art of Flame Straightening Limitations; How Flame Straightening Works; Heat Input; Mappy; Applying the Correction; Straightening Shafts and Tubes; Special Applications of Heat Shrinking; Correcting Weldments

Chapter 11 Sheet Metal Shop Layout Work, Blank Length Calculations; Patterns; The "Yank Method"; Box and Pan Brakes; Forming and Layout of Cones; Tanks and Baffles

Chapter 12 The Abrasion Department Sanding, Grinding, and Abrading; The Good, the Bad, and the Ugly; Radius Grinding

Chapter 13 The Junk Drawer Miscellaneous Tricks Without a Home; Ideas for the Shop Floor

Closing Thoughts

Recommended Reading List

Index

HiTorque Mini Mill

HiTorque Mini Mill Transfer Screw Set, 1/4" - 7/16"

Transfer Screw Set, 1/4" - 7/16"