Model engine plans and kits at LittleMachineShop.com. A full range of tools and accessories for the home shop machinist, including everything for your mini lathe and mini mill.

|

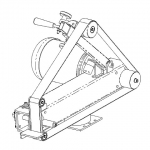

- 17 pages of DIY belt grinder plans

- 18 pages of instructions

- 2" x 72" belt stays sharp longer and cuts cooler than shorter belts

- Use for roughing, shaping, contouring of flat or angular stock

|

|

- Radio controlled 36" model tug boat runs on live steam

- Build the 2 cylinder steam engine from bar stock

- Build the copper boiler

- Build the boat, including propeller and rudder

- Install the radio control

|

|

- Build a crosshead overcrank steam engine

- Video instructions and complete plans on the DVD

- By Ron Takayama

|

|

- Build an overcrank steam engine

- Video instructions and complete plans on the DVD

- By Ron Takayama

|

|

Complete plans to build a unique 5-cyliner steam engine.

These plans were created by Bill Reichart.

This steam engine has 10 pistons and no crankshaft. The plans include six pages of detailed drawings and construction notes. The engine is made from bar stock. No castings are required.

|

|

Complete plans to build an epicyclic steam engine.

These plans were created by Bill Reichart.

This engine uses a unique set of epicyclic gears where one gear revolves around another gear. There are 33 pages of plans that detail every part and describe methods of production. The engine is made from bar stock. No castings are required. You get the gears from Boston Gear.

|

|

Plans to add CNC to a mini lathe.

These CNC conversion plans were created by Ronald J. Steele.

This is a complete set of plans to add CNC to a mini lathe. They include a materials list with sources, plans for all the parts, and instructions for making the parts and installing them on the mini lathe.

Changes to the original machine are minimal. Three drilled and tapped holes are put into the tail end of the lathe bed to hold the Z axis lead screw thrust washer seat/motor mount plate. The remaining motion control parts are either attached via existing holes or clamped onto the machine.

Project completion time is 30 to 40 hours. Cost for mechanical hardware and materials is between $180 and $220. The plans provide several sources for the electrical parts and software.

|

|

Plans to add CNC to a mini mill.

These Mini Mill CNC Conversion plans were created by Ronald J. Steele.

This is a complete set of plans to add CNC to a mini mill. These CNC mill conversion plans include a materials list with sources, plans for all the parts, and instructions for making the parts and installing them on the mini mill.

The only permanent change made to the mini mill is to drill and tap two holes.

Ron Steele says the cost of the hardware and materials, assuming you need to purchase everything, is about $160. The plans provide sources for all these items. The plans also provide several sources for the electrical parts and software. One kit includes software, 145 oz/in stepper motors, and a pre-wired boxed controller and sells for $645. It takes between 20 and 30 hours to machine the parts and bolt it all together.

|

|

Complete plans to build a 4-cylinder, 4-cycle gasoline engine.

These plans were created by Bill Reichart.

The Panther Pup is an air-cooled internal combustion engine. There are 54 pages of plans, bound in a saddle-stitched booklet. The plans include detailed drawings of each part along with complete construction notes.

Two castings are required. Plans are included to make your own patterns, or castings can be purchased from LittleMachineShop.com.

|

|

Complete plans to build a simple steam engine.

These steam engine project plans were created by Bill Reichart.

The Pip-Squeak was designed to be a very first, easy to build engine. It is built from bar stock. No castings are required. It can be made on a small hobby lathe and a small drill press. A small milling machine helps, but isn't necessary.

|

|

- Complete plans to build a model P&H Model 1015 crawler crane

- Crane can be configured with boom length over 9 feet

- USB Flash Drive containing 7 GB including complete plans and annotated construction photos

|

|

The Rike-Vise was invented by Bill Reichart. This simple tool is especially designed for the home machine shop. For many jobs it will replace a standard vise. The Rike-Vise is described as two 90° angle plates joined at the corner, and providing a foot so it can be easily clamped to a machine table or a lathe faceplate. The square donut piece provides an accurate clamp to secure a work piece in the base. It is made of mild steel. The plans include tips on accurately building the vise, plus details on using it.

The plans comprise six 8-1/2" x 11" pages. The plans include information on building and using the Rike-Vise.

Features of the Rike-Vise:

At the lathe you can turn square stock round or drill square stock perfectly concentric.

You can also do the same to rectangular stock, and drill or turn it in the exact center or to one side, as you desire.

The vise holds work perpendicular for drilling at your drill press.

At the milling machine, you can mill an end perfectly square, or notch or groove perfectly parallel to the sides.

It holds stock perpendicular for use at the surface grinder.

|

|

- Complete plans to build a Stirling engine

- Engine is 10" tall when completed

- 26 Pages of plans

|