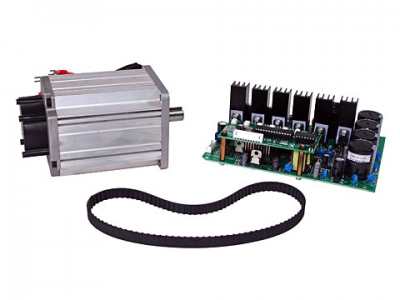

What's the Difference?You might wonder what the difference is between the SIEG Mini Lathe and the HiTorque Mini Lathe or between the SIEG Mini Mill and the HiTorque Mini Mill. They share many of the same features. For example, both mini mills incorporate the large X-Y table. (Visit our mini mill or mini lathe comparison pages for more details.) The most significant difference is the drive system. The photos below show the major components of the two drives.

|

||||||||||||||

Besides simply having more horsepower (500W is

0.67hp, 350W is 0.47hp), the brushless DC drive in the HiTorque mini lathe and

mini mill have greater torque, especially at low speeds. Compare the typical

torque curves.

Besides simply having more horsepower (500W is

0.67hp, 350W is 0.47hp), the brushless DC drive in the HiTorque mini lathe and

mini mill have greater torque, especially at low speeds. Compare the typical

torque curves.

Belt & Disk Sander, 1" x 30" Belt & 5" Disc

Belt & Disk Sander, 1" x 30" Belt & 5" Disc Boring Bar Set, 3/8" Shank, Carbide

Boring Bar Set, 3/8" Shank, Carbide