Turning Tool Nomenclature

Understanding naming conventions for turning tools is interesting, but know that there are no rules about when to use

each tool. Take a look at the job at hand and pick a tool that will do the

job—no matter what it's called.

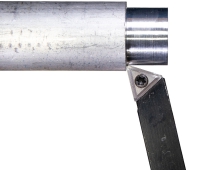

Right Hand Turning Tool

|

A right-hand cutting tool removes metal when moving from right to left.

This is the most common turning activity, cutting towards the lathe chuck.

The cutting edge is on the left side. Tools where the second letter

is "R" are right-hand tools.

Always cut with the point of the insert. The tool shown is at the

proper angle for turning to a 90-degree shoulder. Move

right to left to turn the diameter, then move the tool out to

face the 90-degree shoulder.

|

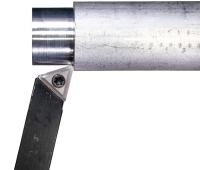

Left Hand Turning Tool

|

A left-hand cutting tool removes material when moving from left to right.

This tool cuts away from the lathe chuck. The cutting edge is on the right

side. Tools where the second letter is "L" are left-hand tools.

Always cut with the point of the insert. The tool shown is at the

proper angle for turning to a 90-degree shoulder. Move

left to right to turn the diameter, then move the tool out to

face the 90-degree shoulder.

|

|

AR Tool Bit

|

The AR-style tool has a 0-degree side cutting angle for general machining

applications such as turning, facing, and chamfering. It's suitable for machining

to a 90-degree shoulder. The cutting edge is on the left for right-to-left feed.

|

AL Tool Bit

|

The AL-style tool has a 0-degree side cutting angle for general

machining applications such as turning, facing, and chamfering.

It's suitable for machining to a 90-degree shoulder. The cutting edge is

on the right for left-to-right feed.

|

BR Tool Bit

|

The BR tool bit has a 15-degree side cutting angle for roughing or heavy

machining when turning and facing. The BR-style tool shape has a lead angle

that distributes the cutting load for interrupted or irregular cuts and

gradual entrance to the workpiece. The cutting edge is on the left for

right-to-left feed. The off side is at a 45-degree angle, which is handy for chamfering.

|

BL Tool Bit

|

The BL tool bit has a 15-degree side cutting angle for roughing or heavy

machining when turning and facing. The BL-style tool shape has a lead angle

that distributes the cutting load for interrupted or irregular cuts and

gradual entrance to the workpiece. The cutting edge is on the right for

left-to-right feed. The off side is at a 45-degree angle, which is handy for chamfering.

|

E Tool Bit

|

The E tool bit has a neutral cutting direction and a sharp tip with a

60-degree angle for threading. It can also be used for chamfering,

notching, V-grooving, and undercutting.

|

|

Plinth Block, Mini Lathe

Plinth Block, Mini Lathe Cut-Off Blade, P1

Cut-Off Blade, P1