HiTorque

HiTorque 3990 Mini Mill

HiTorque 3990 Mini Mill

Out of stock

SKU:3990Shelf Location: (P01 - 01)

Couldn't load pickup availability

Key Features

Key Features

- Most powerful mini mill machine in its class

- Most low-speed torque in its class

- No gears in spindle drive

- Largest table and X-Y travel in its class

- R8 spindle and drill chuck

Share

WARNING: This product can expose you to chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

View full details

Product Information

Description

The LittleMachineShop.com HiTorque Mini Mill is the best in its class. It has the most power, the most torque, and a larger table than other mills in its class.

This mill has a solid column. It does not tilt from side to side. This construction is significantly stiffer than the tilting column on other mini mills. This model also includes the air spring head support for even support through the Z-axis range of travel.

The 500-Watt brushless spindle drive motor provides tremendous low-end torque. And you can vary the speed from 100 rpm to 2500 RPM continuously. There are no gears to shift. And, with no gears, the HiTorque Mini Mill machine is the quietest in its class.

The large mill table provides 50% more table area than other mini mills. It also has 30% more travel in each direction. The resettable feed dials allow you to zero them at any point.

The HiTorque Mini Mill has drill press handles for drilling and fast motion of the mill's head. It also has Z-axis fine feed with 0.001" resolution for milling operations.

This machine is shipped completely assembled and adjusted. Machined surfaces are coated with a viscous oil to prevent rust. It wipes off easily with a rag; no solvents necessary.

The LittleMachineShop.com exclusive version of this machine features:

- 500 Watt output spindle motor

- Large X-Y table

- R8 Spindle for wide tool availability

- Solid column that does not tilt

- NSK brand Japanese bearings

- Gas strut provides even support through the Z-axis range

- Dovetail column maintains head alignment at any height

- Fine feed on Z-axis for precise control

- Three radial handles for drilling

- E-stop safety power switch

- Adjustable Z-axis stop for repetitive drilling

- Neoprene bellows protect horizontal ways

- Adjustable gibs on all dovetail ways

- Includes R8 to 33JT drill chuck arbor and 1/2" drill chuck

The HiTorque Mini Mill comes with the following:

- Mini Mill Users Guide written by Chris Wood

- 2 T-slot nuts with 3/8"-16 thread

- Three open end wrenches (8/10 mm, 14/17 mm, 17/19 mm)

- Four hex (Allen) wrenches (3, 4, 5, and 6 mm)

- One 45-52 mm spanner wrench

- Spindle lock pin

- Oil can (plastic)

- One 1/2" drill chuck and R8/JT33 arbor

The LittleMachineShop.com model 3990 HiTorque Mini Mill is a version of the SIEG X2.

Chris's Tips

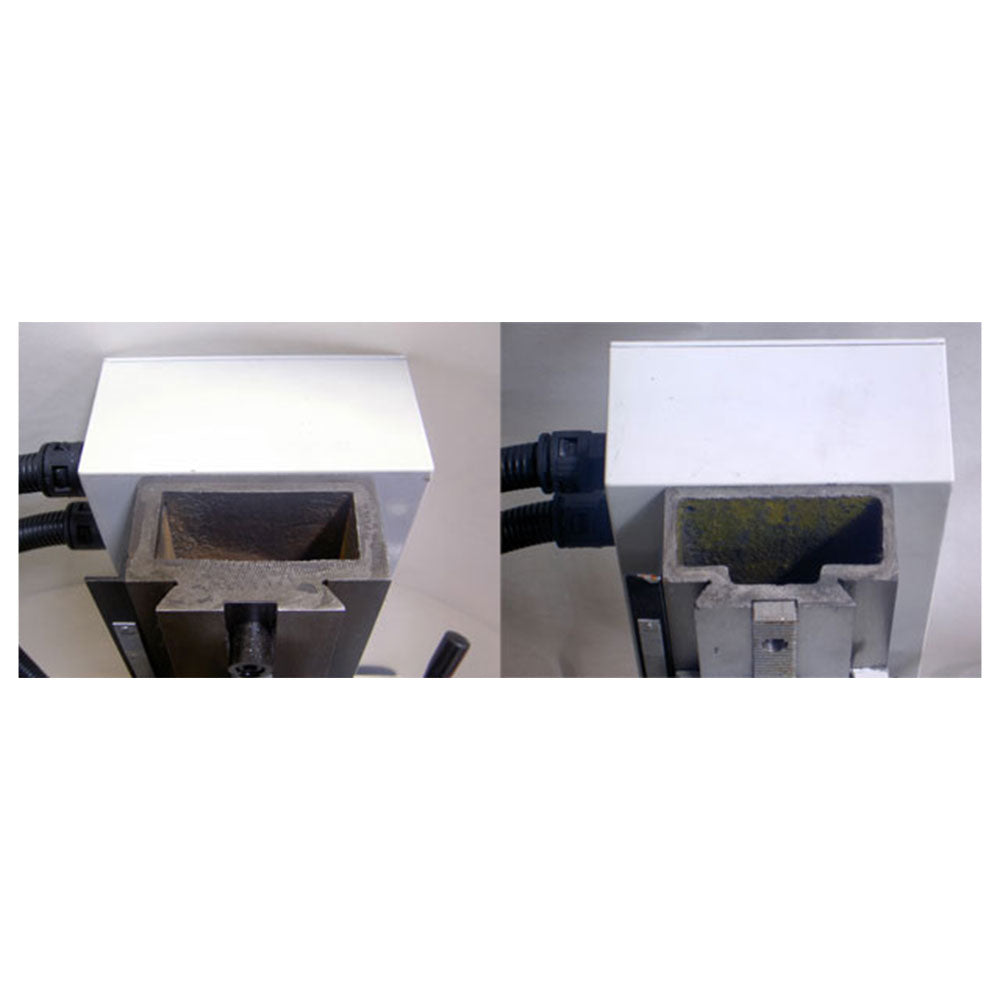

See what the difference is between the SIEG drive system and the HiTorque drive system.

You can compare the specifications for our mills.

Let's compare the LittleMachineShop.com Solid Column HiTorque Mini Mill to mini mills with a tilting column.

The tilting column on other folk's mini mills tilts 45 degrees from side to side and it is possible to make some angled cuts. One user (and only one) has described to me a cut that was impossible to make any way but using a tilting column.

HiTorque mills have a solid column. The solid column has thicker walls than the tilting column, and a stiffer joint where it joins the base, so the column is significantly more rigid than the tilting column. It is not as easy to knock it out of tram as the tilting column mini mill. If you need to cut on an angle... angle blocks, tilting vises, sine vices, fixture plates, etc. are a much better way of ensuring and accurate cut.

LittleMachineShop.com no longer sells mills with a tilting column. That is an indication of how much better the solid column is.

Specifications

End Milling Capacity: 0.630" (16 mm)

Face Milling Capacity: 1.181" (30 mm)

Drilling Capacity: 0.512" (13 mm)

Table Size: 18.110" x 4.724" (460 mm x 120 mm)

T-Slots: 3 slots 0.472" wide,12 mm

X-Axis Travel: 11.811" (300 mm)

Y-Axis Travel: 5.118" (130 mm)

Z-Axis Travel: 10.630" (270 mm)

Throat: 6.496" (165 mm)

X- and Y-Axis Feed Screws: 0.062" (1.59mm) per rotation

Maximum Spindle to Table: 11.496" (292 mm)

Positioning Accuracy: 0.000" (0.01 mm)

Spindle Taper: R8

Spindle Motor: 0.67 hp (500 Watts)

Spindle Speed: 100 to 2500 RPM

Power Requirements: 120 V 60 HZ 8 Amps

Machine Weight: 124 lbs (56 kg)

Base Dimensions (W x D): 8.5" x 14.25" (215.900 mm x 361.950 mm)

Mounting Holes Center to Center (W x D): 7.087" x 11.811" (180 mm x 300 mm)

Overall Dimensions (W x D x H): 23.228" x 19.685" x 36.299" (590 mm x 500 mm x 922 mm)

Crated Weight: 161 lbs (73 kg)

Crate Dimensions (W x D x H): 23.622" x 25.000" x 29.921" (600 mm x 635 mm x 760 mm)

Product Instructions

Don't forget these complementary products...

Specifically designed to work together and improve overall performance

Recommended product category

Browse the XYZ category for more great products

-

Drill Press, Mini Bench Top with Tapping Function

Regular price $349.99 USDRegular priceUnit price / per -

Band Saw Blades, 64-1/2", Intenss PRO-DIE, Individual Sizes, Starrett

Regular price From $34.95 USDRegular priceUnit price / per -

Abrasive Belt, 1" x 30", Individual Grits

Regular price $4.99 USDRegular priceUnit price / per -

Belt, Mini Drill Press

Regular price $8.95 USDRegular priceUnit price / per -

Grinding Wheel Dresser, Single Point Diamond

Regular price $22.95 USDRegular priceUnit price / per -

Band Saw Blades, 44-7/8", Porta-Band Bi-Metal, Individual Sizes, Starrett

Regular price $13.75 USDRegular priceUnit price / per -

Saw Blade, 14" Aluminum, 80T, Evolution

Regular price $124.99 USDRegular priceUnit price / per -

Chop Saw, 14" Metal Cutting, Evolution

Regular price $499.99 USDRegular priceUnit price / per -

Hacksaw Blades, 12", Bi-Metal, Individual Sizes, Starrett

Regular price From $2.25 USDRegular priceUnit price / per -

Hacksaw Frame, Heavy Duty, Starrett

Regular price $65.99 USDRegular priceUnit price / per -

Tooling Package, Drill Press

Regular price $159.95 USDRegular priceUnit price / per -

Grinding Wheels, Individual Sizes

Regular price From $34.95 USDRegular priceUnit price / per