Vise ComparisonThere are several different styles of vise you can choose to use on your mini mill. The following table shows the strengths of each type of vise.

One significant differentiator between vises is the mechanism that holds the movable jaw down as the vise is tightened. If the movable jaw has a tendency to lift as the vise is closed, it can be hard to keep the work piece firmly down on the parallels in the vise. Some vises use a passive mechanism, such as retainers under the vise ways to hold the movable jaw down. These vises count on the accurate adjustment and close tolerances of the retainers to keep the movable jaw in place. Because there must be some clearance to allow the jaw to slide, there is always some upward movement as the jaws are closed. Other vises incorporate an active mechanism that imparts a vertical force to keep the movable jaw firmly down on the ways. These vises make it much easier to keep the work piece firmly on the parallels as you tighten the vise. Quick Vise The quick vise is a light-duty vise. The two best features of the quick vise are its cost and its ease of adjustment. The ratchet mechanism makes adjusting the jaw opening quick and easy.

Milling Vise The milling vise is more rugged than the quick vise, but is still economical and easy to use. The detachable swivel base makes angle adjustments possible. The acme adjusting screw is covered for protection. The milling vise counts on gib-like hold-downs to prevent the movable jaw from lifting. Because there must be some play to allow the jaw to move, there is no way to prevent a small amount of lift as the vise jaws are tightened.

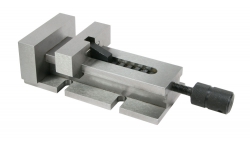

Screwless Vise This vise is called a screwless vise because there is no long adjusting screw running axially the length of the vise. The vise is tightened with a socket head cap screw that pulls down at about a 45° angle. Because of this angle, the movable jaw is pulled down as well as closed when the screw is tightened. This prevents the movable jaw from lifting as the vise is tightened. To move the movable jaw, a cross pin at the bottom of the socket head cap screw must be moved from one hole or groove to another. This is not as convenient as adjusting a normal vise screw. Also, some mechanism must be created or purchased to secure the screwless vise to the mill table. We recommend that you make clamping blocks for this purpose. The screwless vise is a precision vise. It is hardened and ground all over to be square and parallel within 0.0002". There are horizontal and vertical vees on the inside face of the movable jaw to hold round objects (except on the 1" screwless vise).

Precision Milling Vise These vises incorporate a mechanism, originally created by the Kurt Manufacturing Company, that directs a portion of the force from the vise screw into a vertical direction to hold the movable jaw down on the vise base. This helps to prevent the work piece from lifting off the parallels as you tighten the vise. This angle lock mechanism also incorporates a spherical segment that allows the movable jaw to conform to the shape of the work piece, providing an even clamping pressure. (AngLock is a registered trademark of the Kurt Manufacturing Company.)

The precision milling vise also incorporates a ball or needle thrust bearing on the screw shaft for easy operation.

Sine Vise A sine vise is a special-purpose vise designed for holding work at a very accurate angle. A sine vise is not rigid enough for every-day work. It's called a sine vise because you calculate the sine of the angle you want when you set up the vise. The sine vise is a screwless vise that sits on two cylinders. One cylinder is the axis of rotation of the vise body. The second cylinder is positioned very precisely at a known distance from the axis of rotation. Knowing the sine of the angle you want and the length of the hypotenuse (the distance between the centers of the cylinders), you can easily calculate the distance that the movable cylinder should be above the base of the vise. See the height table for the correct height of space blocks for angles from 1 to 60°.  You use space blocks to raise the movable cylinder. Space blocks come in a set of various thicknesses so that you can assemble them to make any distance that the movable cylinder needs to be raised. Each space block has a threaded hole in the center so they can be assembled to form a riser of a specific thickness. .

|

Lathe Chuck - 4", 3-Jaw, Premium, Harlingen

Lathe Chuck - 4", 3-Jaw, Premium, Harlingen Tool Bit, 5/16" x 2-1/2", M2 HSS

Tool Bit, 5/16" x 2-1/2", M2 HSS